-

206-310-3624

206-310-3624

-

support@pcbinternational.com

support@pcbinternational.com

The chart below provides the thickness for a single ply (sheet) of each style of Pre-Preg after processing. These are grouped by the weight and type of the internal conductor layer (typical signal and plane layers) that they will be adjacent to (columns A -F). Those that are adjacent to the top and bottom copper layers will use the column designated for these (column G) regardless of the layer type. All plies that are not directly against a conductor layer (use for situations with more than 2 plies in an opening) will use the additional plies values (column H). These values are based on a minimum of 2 plies of pre-preg per opening between foil and cores or between cores.

If you require more than 15mils (0.38mm) spacing between layers defined as Pre-Preg, an extra blank core will need to be added to the construction and this will affect the cost. Pre-Preg alone cannot be thicker than 15mils since it causes issues with the lamination process. Please contact your PCB International sales representative if you have any questions before placing your order.

The information provided is intended as a guide only. The actual thickness will be affected by the copper distribution within the design as well as within the production panels.

| A | B | C | D | E | F | G | H | |

|---|---|---|---|---|---|---|---|---|

| Pre-Preg Styles | Against core with .5 oz copper and signal traces utilizing 30% of the board area |

Against core with .5 oz copper and plane utilizing 70% of the board area |

Against core with 1oz copper and signal traces utilizing 30% of the board area |

Against core with 1 oz copper and plane utilizing 70% of the board area |

Against core with 2 oz copper and signaltraces utilizing 30% of the board area |

Against core with 2 oz copper and plane utilizing 70% of the board area |

Against the top and bottom copper layers (foil) | Additional plies that are not directly against conductor layers |

| 106 | 1.9 | 2.2 | 1.5 | 2.0 | 0.5 | 1.5 | 2.3 | 2.1 |

| 1080 | 2.6 | 2.8 | 2.1 | 2.6 | 1.1 | 2.2 | 3.0 | 2.7 |

| 2113 | 3.5 | 3.7 | 3.0 | 3.5 | 2.0 | 3.1 | 3.9 | 3.5 |

| 2116 | 4.7 | 4.9 | 4.2 | 4.7 | 3.2 | 4.3 | 5.1 | 4.6 |

| 7628 | 6.5 | 6.8 | 6.0 | 6.5 | 5.0 | 6.1 | 6.9 | 6.2 |

All thickness values are in mils. (1/1000 inch)

The dielectric thickness requirements supplied with an order will be interpreted with a minimum 10% tolerance.

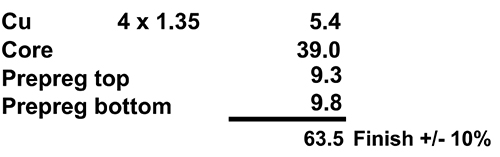

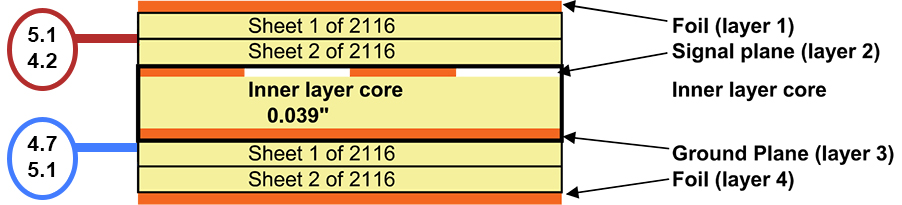

The stack-up for our typical 0.062'' 4 layer with one ground and one signal plane using 1 oz Cu and two sheets of 2116 pre-preg on each side of the core would look like this

The spacing between the top layer and the signal core would finish at about 9.3 mils From the ground core to the bottom foil would be approximately 9.8mils. Add to that the core thickness of .039 & the four layers of 1 ounce Cu at 1.35 each